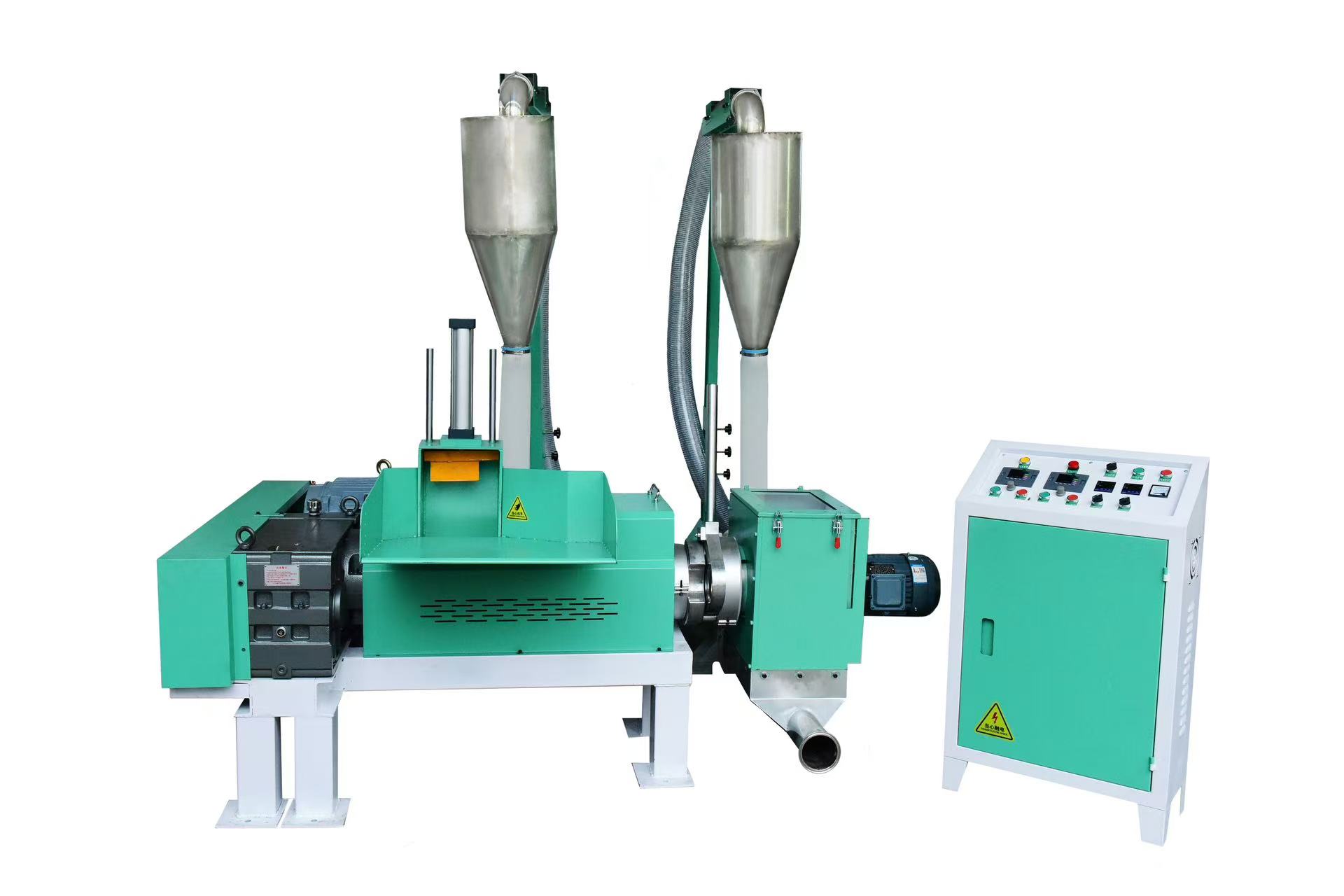

The main machine of plastic pelletizer is extruder, which is composed of extrusion system, transmission system and heating and cooling system. Vigorously develop renewable resources, turning waste into treasure. Extruding system The extruding system includes hopper and head, the plastic is plasticized into uniform melt through the extruding system, and is continuously extruded out of the head by the screw under the pressure established in the process. Screw: is the most important part of the extruder, it is directly related to the application range and productivity of the extruder, made of high-strength corrosion-resistant alloy steel. Barrel: is a metal cylinder, generally heat-resistant, high compressive strength, strong wear-resistant, corrosion-resistant alloy steel or alloy steel lined with composite steel pipe made. Cylinder and screw cooperation, to achieve the plastic crushing, softening, melting, plasticizing, exhaust and compaction, and to the molding system continuous and uniform delivery of rubber. Generally the length of the barrel is 15-30 times of its diameter, so that the plastic can be fully heated and fully plasticized as a principle.

The plastic granulator adopts special screw design and different configurations, which is suitable for producing PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA and other plastics for regeneration and color mixing granulation. The reduction gearbox adopts high torque design, realizing noiseless and smooth running and other properties. The screw and barrel are treated with special hardening treatment, which has the characteristics of wear-resistant, good mixing performance and high output. The design of vacuum exhaust or common exhaust port can exhaust the moisture and exhaust gas away during the production process, so that the material is more stable and the rubber granule is more solid, which ensures the excellent quality of the products. Plastic granulator is mainly used for processing waste plastic film (industrial packaging film, agricultural mulch, greenhouse film, beer bags, handbags, etc.), woven bags, agricultural convenience bags, pots, buckets, beverage bottles, furniture, daily necessities, etc., for most common waste plastics, waste plastic regeneration industry is the use of the use of plastic regeneration industry, use of the pan, the user is welcome to the plastic recycling processing machinery.

If you are interested in plastic granulators, please contact us to discuss customized solutions to create a circular economy for your business.