With the booming development of the plastics industry, the production and application of plastic profiles and sheets are becoming more and more widespread. However, the disposal of waste materials and discarded plastics generated during the production process has also become an environmental problem that needs to be solved urgently. Traditional plastic pelletizing methods, such as water-cooled pelletizing, can achieve recycling and reuse of waste materials, but there are high energy consumption, large footprint, complex operation and other shortcomings. In recent years, the emergence of air-cooled low-temperature crushing and pelletizing technology has brought a new solution for the recycling of plastic profiles and sheets.

Limitations of traditional water-cooled pelletizing

Most of the traditional screw extrusion waste plastic pelletizing, water-cooled method. Although this method can effectively cool the molten plastic, but there are several shortcomings:

High energy consumption: water cooling system needs to consume a lot of water resources and electricity, which increases the production cost and puts a certain burden on the environment.

Large footprint: Water cooling systems are usually complex and require a large footprint, limiting the layout of the production line.

Complicated operation: Water-cooled systems require regular maintenance and cleaning, making operation relatively complicated and increasing labor costs.

Particles containing water: water-cooled granulation particles, the surface of the residual water, the need for subsequent drying treatment, increasing the process.

Advantages of air-cooled low-temperature crushing granulation

In contrast, air-cooled low-temperature crushing granulation technology has significant advantages:

Low-temperature crushing, low energy consumption: air-cooled system using air cooling, without the need to consume large amounts of water resources, and low-temperature crushing technology can effectively reduce energy consumption, energy saving and emission reduction.

Small footprint: air-cooled system is compact, small footprint, easy to layout the production line, improve the site utilization rate.

Simple operation: the air-cooled system is easy to operate, only one operator can complete the entire granulation process, reducing labor costs.

High quality of granules: the granules after air-cooled granulation are compact, uniform, high density, unbreakable and of good quality, which can be directly used in subsequent production.

No need for drying treatment: the surface of air-cooled pellets is dry, no need for subsequent drying treatment, simplifying the process.

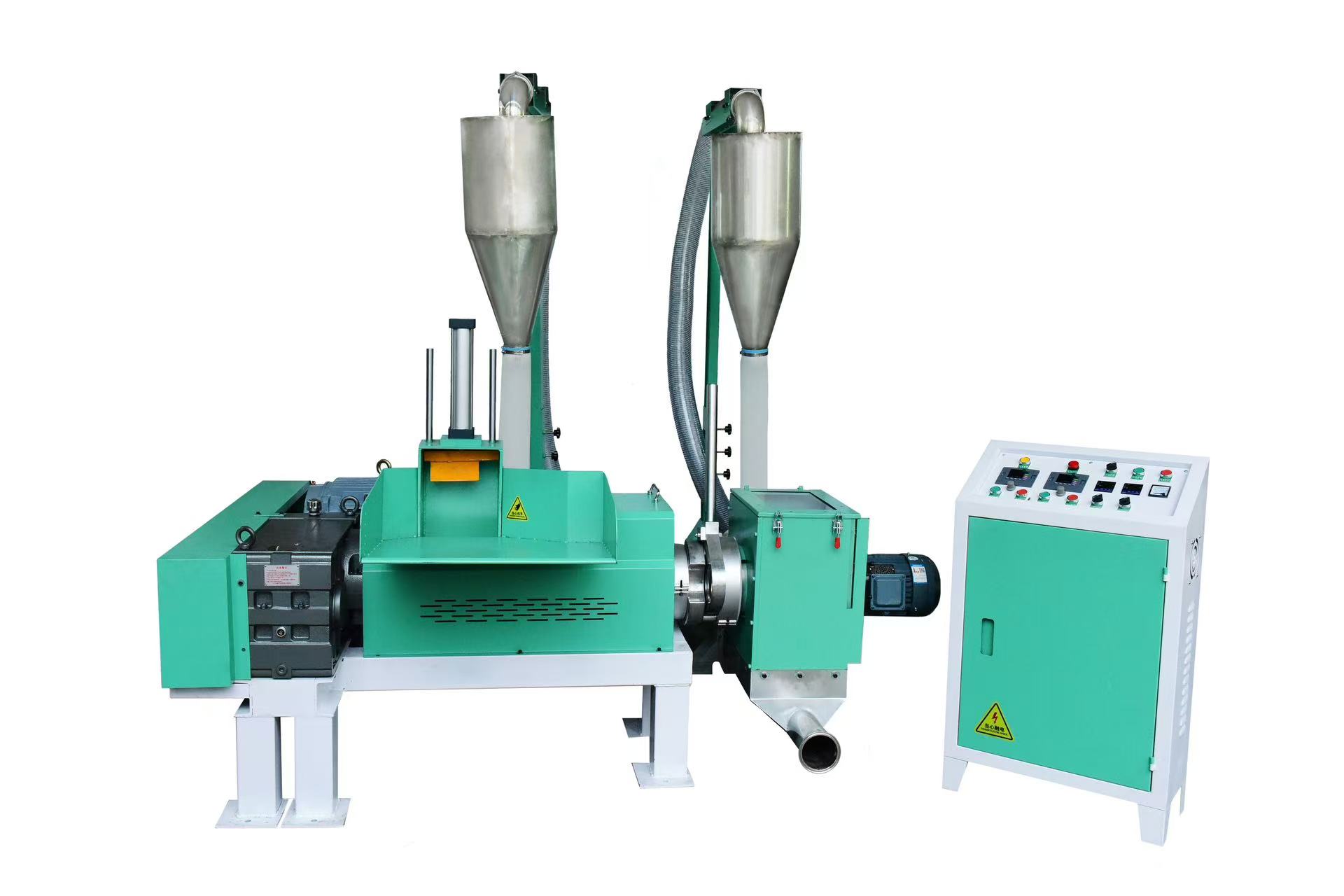

If you want to know more about Plastic Waterless Cold Cutting Granulator, please leave your message to us below.