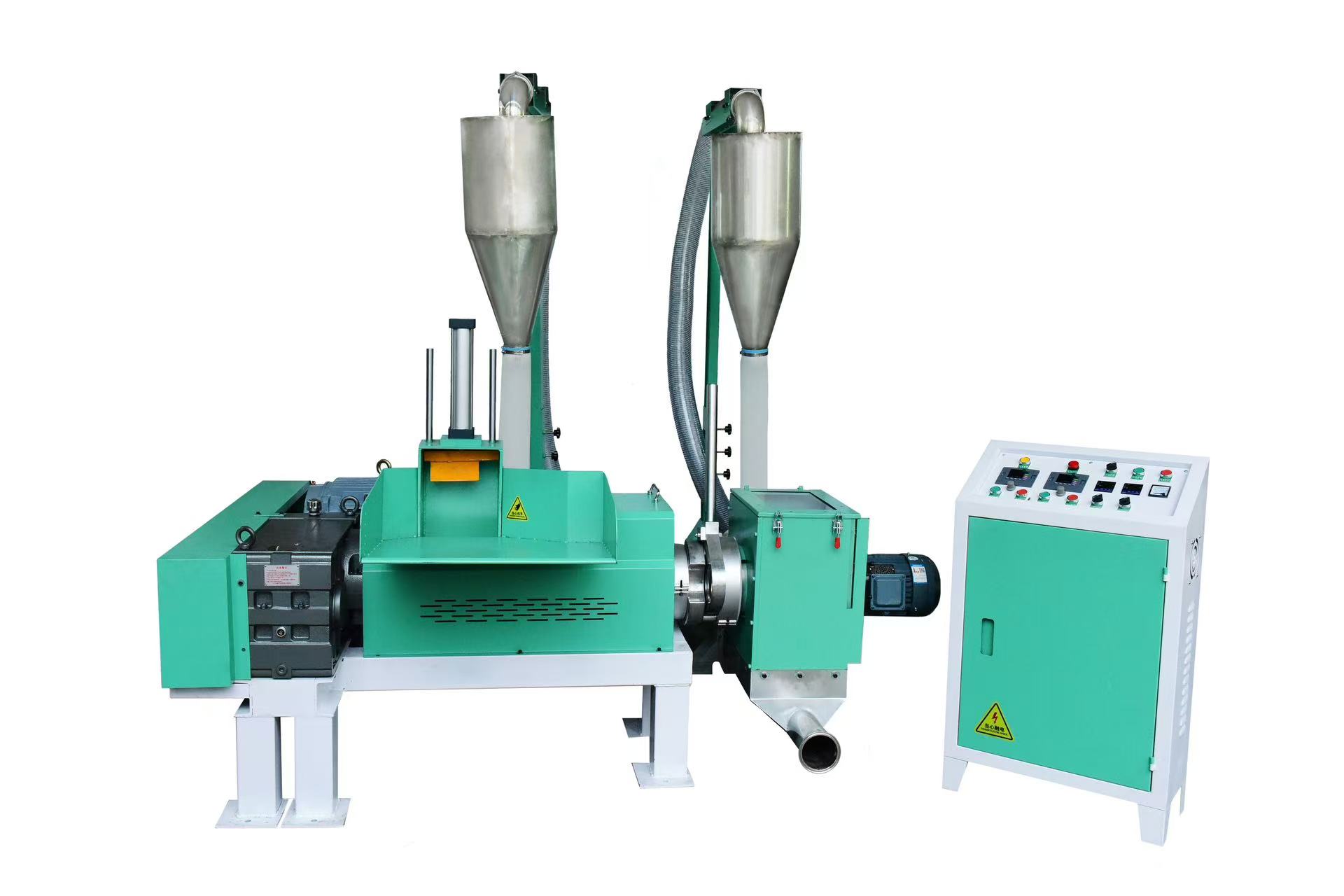

Advantages of air-cooled pelletizer

In recent years, the air-cooled pelletizer, as a new type of plastic waste treatment equipment, has received widespread attention. It adopts low-temperature crushing technology, which can transform various plastic wastes into reusable granules with the following significant advantages:

High efficiency and environmental protection: The air-cooled pelletizer operates at low temperature without water cooling, which avoids the waste of water and water pollution. At the same time, it does not produce smoke and odor in the crushing process, reducing air pollution.

Wide range of applications: It is suitable for a wide range of plastic materials, including LDPE, LLDPE, HDPE, CPE, PVC, TPU, PLA and degradable plastics. This makes it possible to handle many types of plastic waste and increase the recycling rate.

Easy to operate: The operation interface is user-friendly and only requires a few buttons to complete the operation. Even unskilled workers can easily get started, reducing operation difficulty and labor costs.

Energy saving and consumption reduction: air-cooled pelletizer adopts advanced energy-saving technology, low energy consumption during operation, reducing operating costs.

No secondary pollution: in the crushing process, no waste water and harmful gases, avoiding secondary pollution.

If you want to know more about Plastic Waterless Cold Cutting Granulator, please leave your message to us below.