- Home

- Plastic Film Blowing Machine

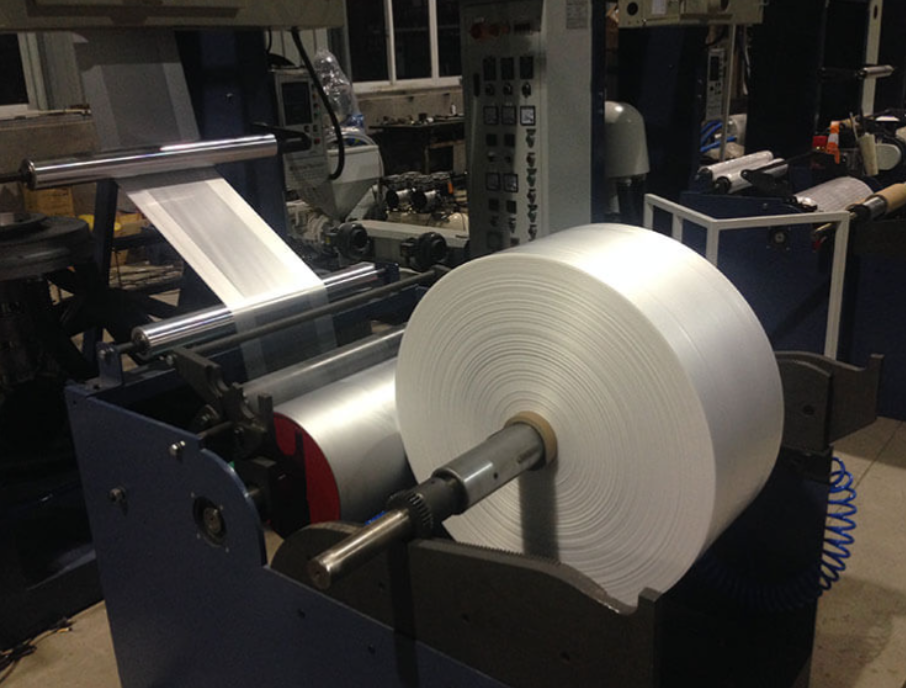

- 2-Layer Blown Film Machine/flat blowing/standing blowing/high and low pressure blown film machine (support customization)-RC-H/L/2L

2-Layer Blown Film Machine/flat blowing/standing blowing/high and low pressure blown film machine (support customization)-RC-H/L/2L

Product Description:

Our AB double-layer co-extruded film blowing machine line is suitable for blowing high-density polyethylene, low-density polyethylene and linear low-density polyethylene, and the products are widely used in express bag film and two-color film.

Forced feeding mainframe: Aoxiang’s mainframe adopts double alloy forced feeding screw, which has excellent hardness and abrasion resistance, and can still ensure the plasticization of a large number of particles in response to the environment of high rotational speed and high pressure. The service life can be 3-5 times that of ordinary screws.

Conical stacked molds: The double-layer co-extruded blown film machine line adopts double-layer conical stacked molds. We have optimized the layout by means of thermo-fluidics and observed the fluids with the help of 3D simulation software. We are sure that after highly polished and coated process, by the high pressure of Aoxiang high speed screw, high speed flushing, each runner has self-cleaning ability. This reduces the waste in the particle replacement process and reduces the downtime for maintenance.

Advanced automation module: The double-layer co-extruded blown film machine line has advanced automation functions, centralized feeding, dosing, grammage control, full-automatic center winding and so on. All integrated in the touch screen integrated control. It makes the operation easier and the production efficiency is improved. Packaging of fruits, meat, pickles, etc.

Packing and Delivery:

Contact Us For A Quote!

Related products

-

Three-layer co-extrusion blown film machine consists of three single-screw extruders, three-layer composite co-extrusion molds, cooling system, haul-off machine, film winding device, temperature and electric control system, etc. It is mainly used to produce three-layer co-extruded composite film with width of 1600-2600mm. (Support customization)

Read more