- Home

- Plastic Mixer

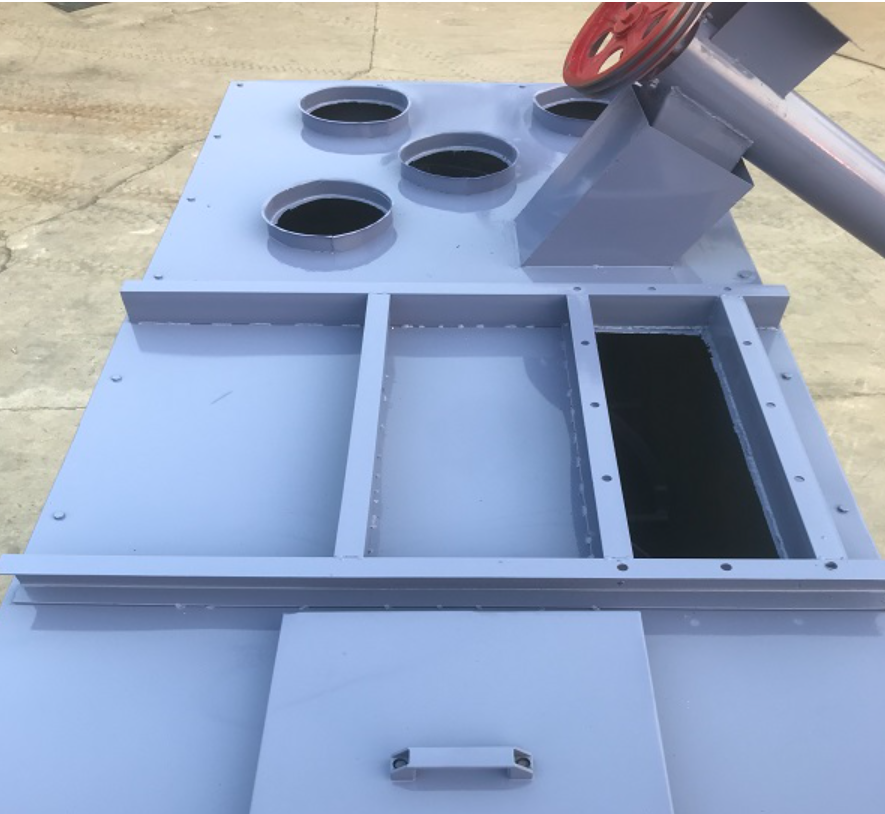

- Double shaft horizontal mixer Hot sale plastic recycling machine auxiliary (support customization)

Double shaft horizontal mixer Hot sale plastic recycling machine auxiliary (support customization)

Product Description:

Twin shaft horizontal mixer barrel is equipped with rotating reverse slurry leaves, the slurry leaves into a certain angle will be the material along the axial and radial circulation stirring, so that the material is quickly mixed evenly. Double shaft horizontal mixer is driven by the motor through the belt transmission to the reducer to drive the shaft rotation. The speed of the shaft and the structure of the paddle will make the material gravity weakened, with the lack of gravity, the existence of each material particle size, specific gravity of the disparity between the differences in the mixing process is ignored. The intense mixing motion shortens the time of one mixing, which is faster and more efficient. Even if the materials have the difference of specific gravity and particle size, under the fast and violent tossing and throwing of the interlaced mixing blades, a good mixing effect can be achieved.

Double shaft horizontal mixer has high mixing degree and less residue, suitable for mixing more than two kinds of fertilizers, additives premix, and mixing of compound feed, concentrated feed, additives premixed feed and so on. Specific features are: the material is fully mixed, thus improving the mixing uniformity; the use of novel rotor structure, effectively reducing the amount of material residue. The special rotor design of the machine can also crush larger materials. The overall structure is more reasonable, beautiful appearance, easy to operate and maintain.

Mixing effect of double shaft horizontal mixer:

The mixing process of double horizontal shaft mixer occurs not only in the radial direction, but also in the axial direction. The main mixing zone is located in the circumferential direction of the mixing body, and the energy value along this direction reaches *** during the whole mixing process, so the mixing space can be fully utilized to make the aggregate, cement and water reach the highest value in the shortest time under the circumstance of low circumferential speed of the mixing blades (1.4~1.6m/s)? In the shortest time to achieve the most uniform *** mixing mode, to achieve *** mixing effect. Double shaft horizontal mixer wear resistance:

The mixing principle and process of the double horizontal shaft mixer ensures that most of the mixed concrete is piled up between the two mixing shafts, which makes the wear and tear between the mixing arms and blades and the bottom liner plate lower. Practice has proved that only 25% of the blades in the non-main mixing zone have wear phenomenon, and in the main mixing zone there is only slight wear, or even no wear, double horizontal shaft mixer liner can be selected according to the operating conditions of ordinary steel plate or wear-resistant cast iron.

Double horizontal shaft mixer discharge performance:

Since the concrete is basically piled up near the discharge gate when the double horizontal shaft mixer finishes mixing, the time taken for discharging is short. The opening degree of the discharge door controlled by electric device can be adjusted, and the discharge door will not be jammed when it is closed. During the discharging process, the blades rotate at a low speed, which is conducive to removing the concrete left in the mixing drum, and can effectively avoid the throwing phenomenon when discharging the pan-type machine. Load starting characteristics of double shaft horizontal mixer:

As the mixing arm of double horizontal shaft mixer is shorter and with lubrication system, it is installed with hydrostatic starter, so it is able to start the main motor under the condition of full load. During operation, the mixer is usually required to be started under extra-ordinary conditions.

Packing and Delivery: