In today’s increasingly focus on environmental protection and sustainable development, stretch film factories are facing unprecedented challenges and opportunities. How to reduce production costs, improve resource utilization and realize green production has become an important issue in front of every factory owner. An efficient, environmentally friendly, energy-saving recycling granulator is undoubtedly the ideal choice to solve these problems.

Environmental protection and energy saving, green production of a powerful booster

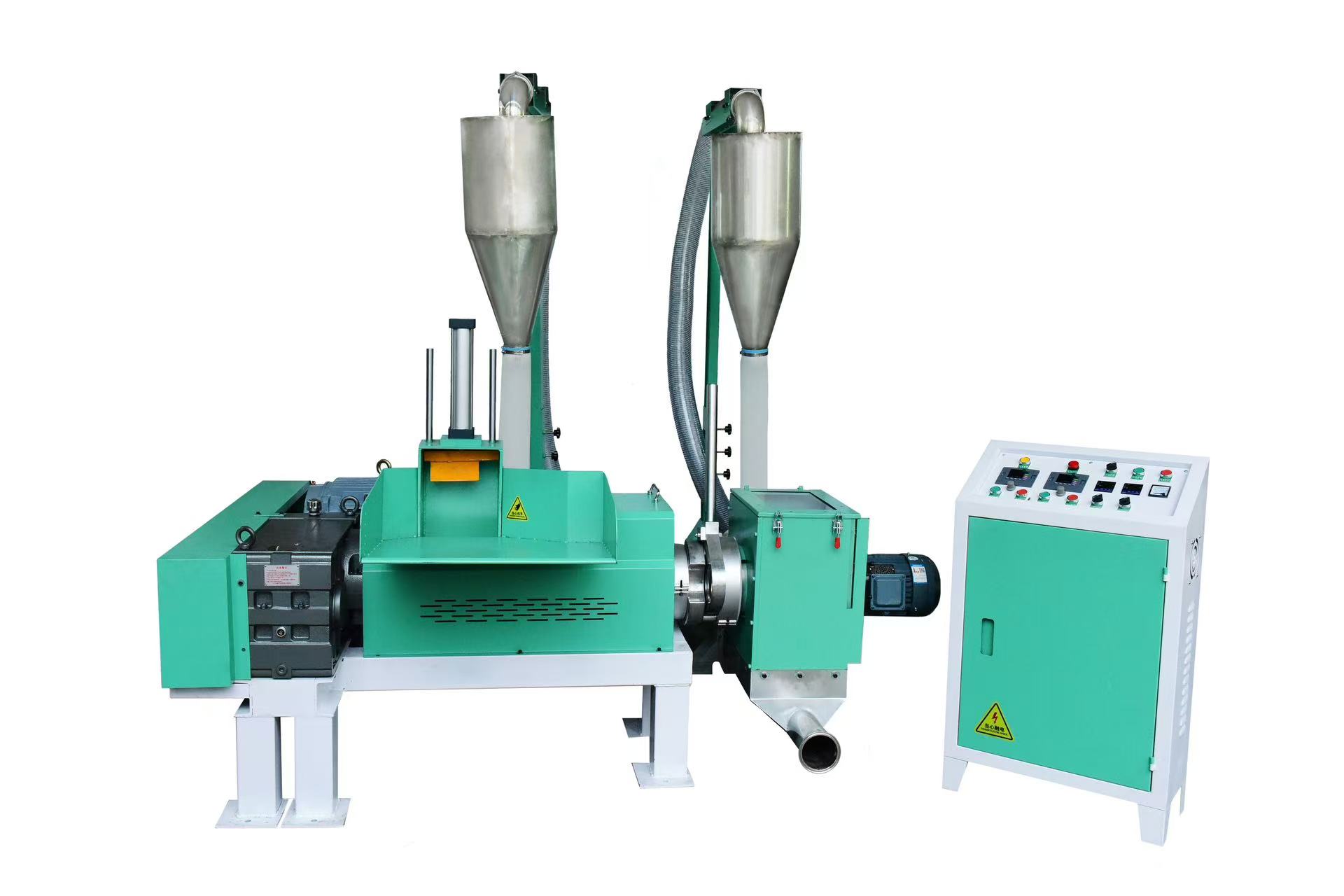

This environmentally friendly and energy-saving recycling granulator adopts advanced production technology and techniques to realize environmentally friendly production without smoke, water and odor. The traditional granulator produces a lot of waste gas, waste water and noise during the production process, causing serious pollution to the environment. And this new granulator effectively reduces pollutant emissions and realizes clean production through optimized design and fine control.

At the same time, this equipment also excels in energy saving. It adopts energy efficient heating system and intelligent control system, which effectively reduces energy consumption. Compared with the traditional granulator, it can save a lot of electricity and fuel, saving considerable production costs for the factory.

Recycling and reuse, ideal for turning waste into treasure

Stretch film production process will produce a large amount of waste and trimmings, these wastes, if not properly handled, will not only cause a waste of resources, but also cause pollution to the environment. This recycling granulator can recycle these wastes and turn them into reusable plastic pellets.

Through recycling, factories can effectively reduce the cost of raw materials, reduce the dependence on new materials, and realize resource recycling. At the same time, it also helps to reduce waste emissions, reduce environmental pollution and enhance the environmental image of the enterprise.

Easy to operate, improve production efficiency

The equipment plastic granulator adopts humanized design, easy to operate and easy to start. Even without professional technicians, it can be easily operated. Intelligent control system can realize automatic production, reduce manual intervention and improve production efficiency.

In addition, the equipment also has the advantages of stable operation and low failure rate, which can ensure the continuous and stable operation of the production line, reduce downtime and improve production efficiency.

Return on investment, help enterprises sustainable development

Although the purchase of environmentally friendly energy-saving recycling granulator requires a certain investment, but in the long run, it is a very worthwhile investment. By reducing energy consumption, minimizing raw material costs, and improving production efficiency, factories can recover their investment costs in a short period of time.

What’s more, this plastic granulator equipment helps to improve the environmental image of the enterprise, enhance its market competitiveness, and lay a solid foundation for its sustainable development.

For stretch film factory owners, choosing an environmentally friendly and energy-saving recycling granulator is not only a contribution to environmental protection, but also a long-term investment in the enterprise’s own development. This smoke-free, water-free, odorless environmental protection equipment will help your factory to realize green production, improve resource utilization, reduce production costs and achieve sustainable development.

If interested in plastic granulators, please contact us to discuss customized solutions for your business to create a circular economy.