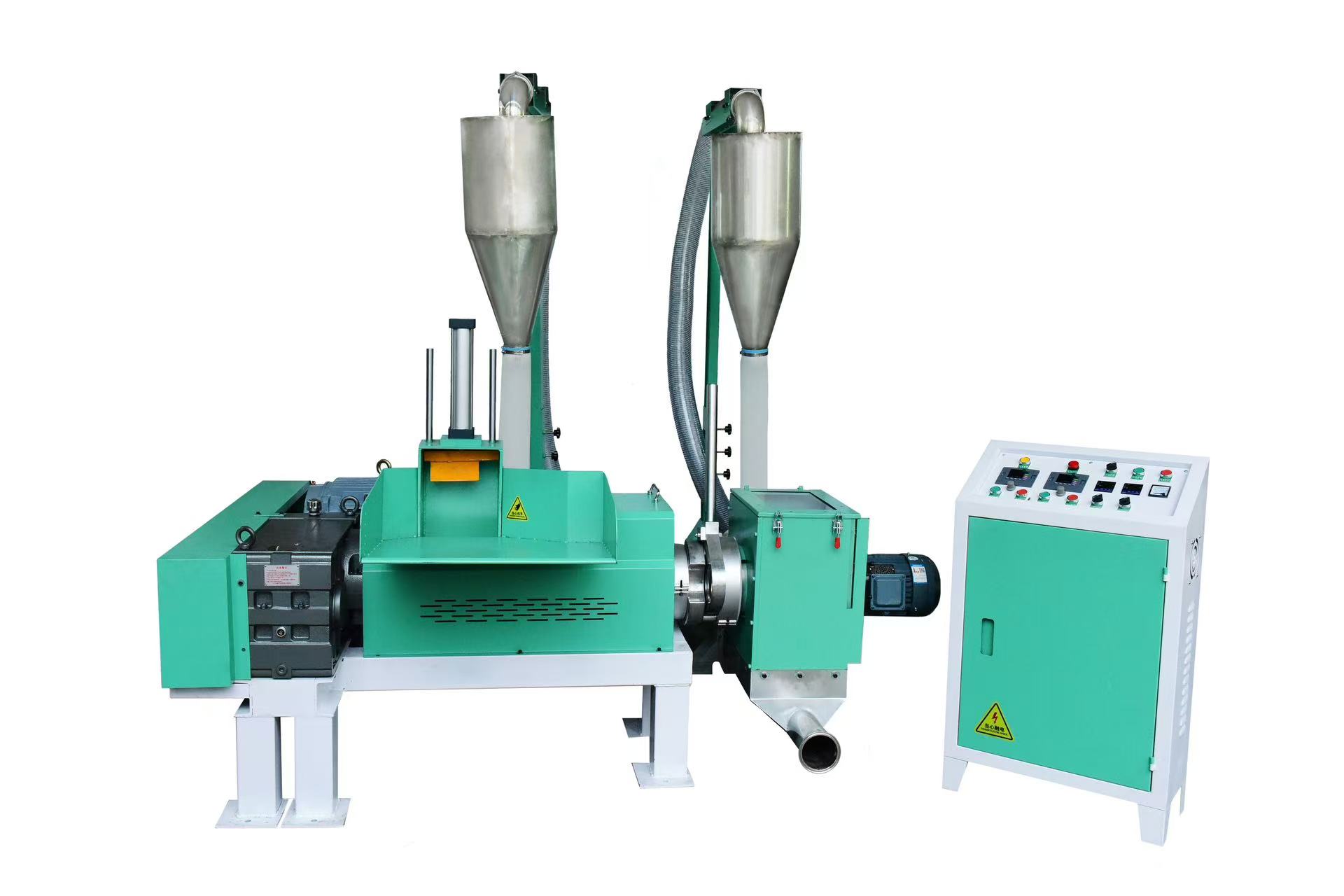

Twin-screw granulator is a kind of high-efficiency mixing and granulating equipment widely used in plastic, rubber, chemical and other industries. Its production process mainly includes the following steps:

Raw material preparation

Selection of raw materials**: select suitable raw materials according to product requirements, such as plastic resin, rubber, additives, etc.

Pre-treatment**: Pre-treatment of raw materials such as drying, crushing, mixing, etc. to remove moisture and ensure the uniformity of raw materials.

Feeding System

Metering feeding**: Metering feeding device is adopted to automatically control the feeding amount of raw materials and ensure stable feeding speed.

Forced feeding**: For raw materials with poor fluidity, screw feeder or vibrating feeder can be used to force the materials into the extruder.

Twin-screw extrusion system

Heating and melting**: After the material enters the twin-screw pelletiser, it is heated to a molten state by means of a heating device (e.g. electric heating, steam heating or hot oil heating).

Mixing and Plasticising**: Under the action of the twin-screw, the molten materials are fully mixed and plasticised to form a uniform melt.

Exhaust**: The moisture and volatiles in the material are discharged through the exhaust device to ensure the quality of the product.

Extrusion moulding

Extrusion moulding**: After mixing and plasticising and exhausting, the material is extruded into strips or sheets through the machine head. The shape and size of the head can be adjusted according to product requirements.

Cooling and curing**: The extruded material is rapidly cooled and cured by water or air cooling device to make it into shape.

Pelletising system

Pelletising**: The cooled and cured material is cut into granules of the required shape and size by the pelletiser.

Post-processing

Pellet Screening**: Unqualified pellets and impurities are removed by screening device to ensure product quality.

Packaging and Storage**: Qualified granule products are packaged and stored in a dry and ventilated warehouse.

Process control and quality inspection

Process parameter control**: real-time monitoring and adjustment of process parameters such as temperature, pressure, rotating speed, feeding volume, etc. to ensure production efficiency and product quality.

Quality Inspection**: The finished products are inspected for appearance, size, density, mechanical properties, etc. to ensure compliance with standards.

Summary

The twin-screw granulator is capable of producing high-quality granular products through efficient mixing, melting and granulating processes. With its high degree of automation, it is suitable for a wide range of raw materials and complex production processes, and is widely used in plastics, rubber, chemical and other industries.

If you need a plastic granulator – you can send me a message!