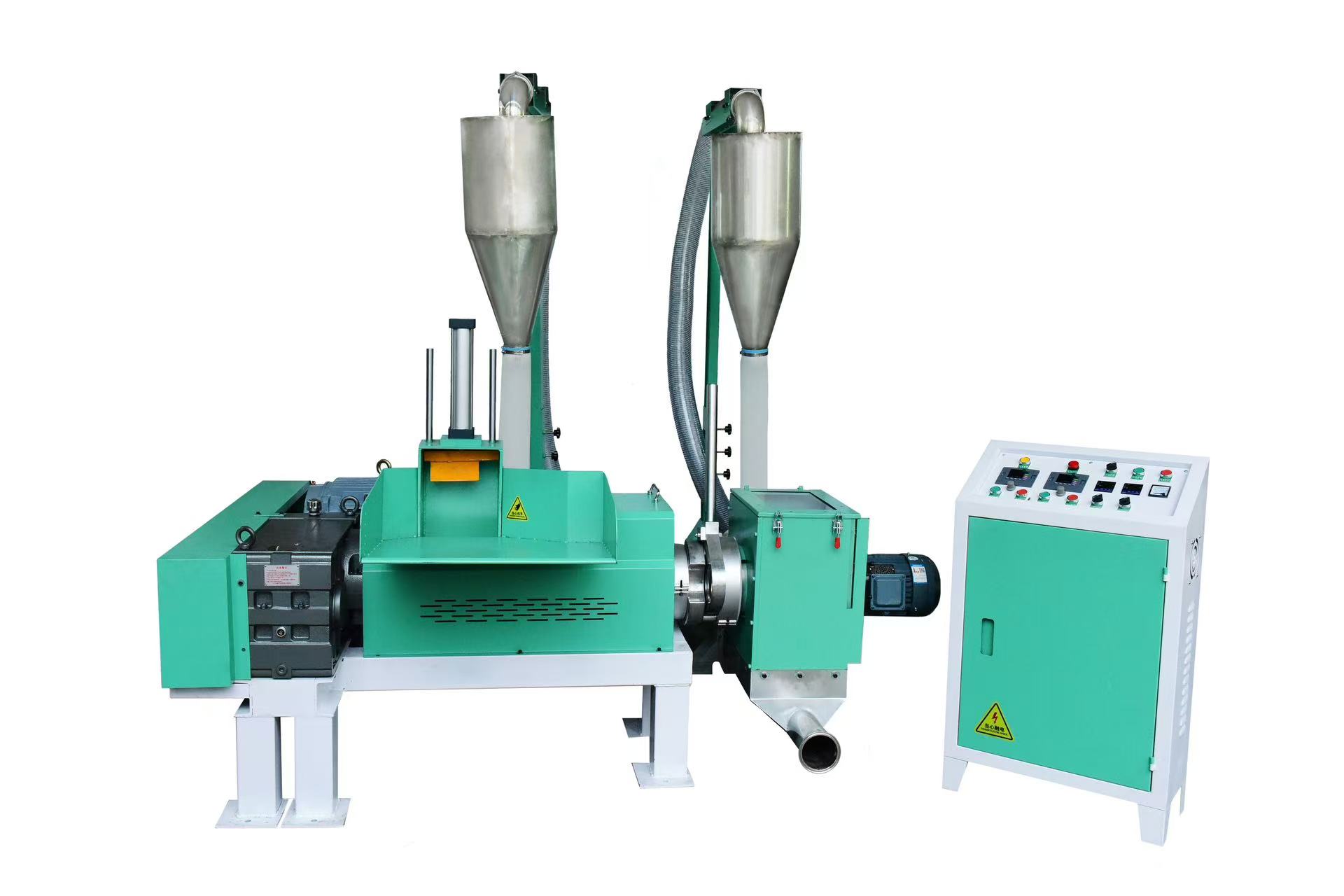

Plastic crusher is a mechanical device specially used to crush waste plastic into particles or powder. With the increasing awareness of environmental protection, plastic recycling and reuse are becoming more and more important, and plastic crusher is one of the key equipment to achieve this goal.

Classification of plastic crusher

According to the different crushing methods and application ranges, plastic crushers can be divided into the following categories:

Single-shaft shredder: Mainly used to process large pieces of plastic, such as waste plastic barrels, plastic products, etc.

Double-shaft shredder: It has strong shredding ability and is suitable for processing various hard plastics and tough plastics.

Hammer crusher: It breaks plastic into particles through high-speed rotating hammers and is suitable for processing various types of plastics.

Grinding machine: It further crushes plastic particles into fine powder for secondary processing of plastic products.

Principle of plastic crusher

The principle of plastic crusher is relatively simple: put waste plastic into the machine and crush the plastic into the required particle size through mechanical force. Different crushers use different crushing methods, but their basic principle is to break down plastic materials into smaller particles.

Application of plastic pulverizer

Plastic pulverizer plays a vital role in the plastic recycling industry. Its main applications include:

Plastic product recycling: crush waste plastic products into particles as raw materials for recycled plastics.

Plastic product manufacturing: mix crushed plastic particles with new materials for the production of new plastic products.

Plastic filler production: crush plastic into fine powder as filler for other materials.

Advantages of plastic pulverizer

Environmental benefits: reduce the generation of plastic waste and protect the environment.

Economic benefits: reduce the cost of plastic raw materials and improve corporate competitiveness.

High resource utilization: convert waste plastics into new resources and realize the recycling of resources.

Selection of plastic pulverizer

When choosing a plastic pulverizer, the following factors need to be considered:

Plastic material: different plastic materials require different pulverizers.

Particle size: select the appropriate particle size according to the requirements of subsequent processing.

Production capacity: select the appropriate equipment according to the production scale.

Noise and dust: select low-noise and low-dust equipment.

Future development of plastic pulverizer

With the increasing severity of plastic pollution, the plastic recycling industry will usher in greater development opportunities. As an important equipment for plastic recycling, the technology of plastic crusher will continue to upgrade to meet the market demand for higher efficiency and higher environmental protection requirements. In the future, plastic crusher will develop in the direction of intelligence, automation, energy saving and environmental protection.

Summary

Plastic crusher plays an important role in the plastic recycling industry and has made great contributions to the realization of plastic circular economy. With the continuous advancement of technology, plastic crusher will play a greater role in the future.

If you are interested in crusher, please leave us a message below.